In case you missed our recent announcement, we now offer virtual installations and service calls using augmented reality (check the coverage we received from Canadian Manufacturing, the Augmented Reality for Enterprise Alliance, and Food Industry Executive).

Augmented reality isn’t a new technology — in fact, it’s been around since the early ‘90s. But its application in manufacturing is just starting to take off, partially aided by the current pandemic, which has caused a temporary suspension of in-person site visits.

In this article, we’ll take a quick step back to look at exactly what AR is and then explore the many ways manufacturers and other industrial equipment buyers can benefit from this technology.

What is augmented reality?

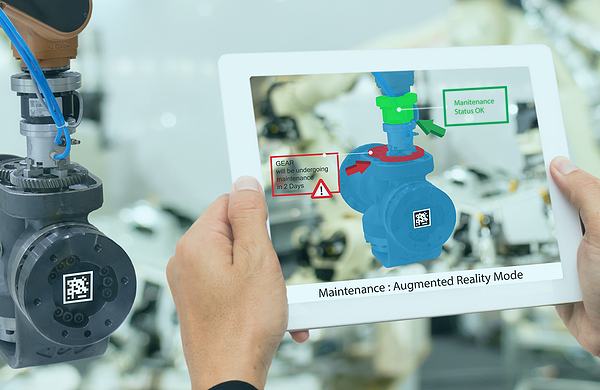

Augmented reality (AR) is a virtual environment where computer-generated information is superimposed onto the real world. The real-world component is what distinguishes augmented reality from virtual reality — VR is entirely computer-generated.

The best way to understand what augmented reality is capable of is to see it in action. On the consumer side, AR is being used for gaming, travel experiences, navigation, and more. The next section explores some innovative ways the manufacturing industry is harnessing the power of AR.

Augmented reality in the manufacturing industry

Equipment design and configuration

For custom-engineered equipment, AR can be used to superimpose digital images of machines onto a plant floor, allowing OEMs and their customers to visualize what the equipment will look like in the facility before it’s built and installed. This can help reveal any design changes that need to be made early on in the process, before those changes incur a hefty price tag. Caterpillar has been a pioneer in using AR to visualize how their equipment will fit into a defined space, as well as several of the other applications on this list.

Equipment sales and marketing

In the past few years, AR has been gaining popularity at trade shows because it allows OEMs to “expand their booth” by digitally displaying equipment that it would be too expensive to transport. The technology also provides a way for potential buyers to assess equipment without having to physically visit the OEM’s plant.

Virtual installations and service calls

Virtual installations and, in particular, service calls, are where we’ve seen the biggest adoption of AR technology. Especially right now, when the pandemic has halted most business travel and many manufacturing plants are closed to outside visitors, the ability to install and service equipment remotely is essential for keeping production lines running.

For our virtual installations and service calls, we use a Vuzix M300XL AR headset, which has full audio and a visual system that makes it seem like a 7” screen is floating in front of the user. Using this headset, our in-house engineer can guide the on-site technician through whatever installation or troubleshooting activities are required. The engineers can also share feeds from a white board or computer.

Learn more about Garvey’s virtual installations and service calls.

Assembly

For products requiring complex assembly, like cars, AR can help operators make sure every part is produced to spec and that all parts are correctly assembled. Porsche, which has been a major adopter of AR across its operations, uses the technology for assembly and QR testing, among other things. (If you’re looking for something fun to do this evening, Porsche also has an AR visualizer that you can use to customize your dream car and then see how it would look in your garage…or your living room.)

Inspections

Individuals performing inspections, whether as part of internal quality assurance programs or for third-party certifications, typically rely on written and photographic records to make their assessments. With AR, they can overlay this historical information onto the current equipment to quickly examine both. As an example, in Canada, the Augmented Reality for Maintenance and Inspection research consortium is dedicated to creating an “AR engine” to aid inspections and maintenance in the transportation industry.

Employee training

According the VR/AR Association, there are now more than 100 companies working on AR systems for employee training. In the manufacturing industry, AR brings training out of the classroom and onto the plant floor. By simulating on-the-job training, the digital technology can decrease training time — one company in the semiconductor industry has seen training time reductions of as much as 50%. AR can also help employers overcome language barriers by providing information in a more accessible visual format.

As far as we know, these represent the main ways the manufacturing industry currently uses AR to improve operations. We expect that over the next several years, more types of solutions will become available. We look forward to being a part of that future!