Cold Room Food Production Solutions

Heat & Eat | Heat & Serve | Convenience Meals

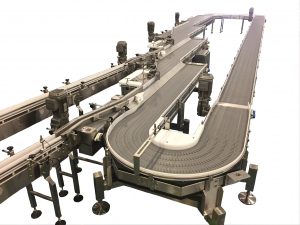

Introducing Garvey’s New Product Solution for Frozen and Refrigerated Food Production

Key Features & Benefits

Precision Orientation: Ensures meals and food items are perfectly aligned for the next packaging stage.

- 3D Chute – Unique to Garvey’s process, enables passive orientation

- Passive or Non-Contact Orientation – In most cases, the orientation is handled passively without mechanical arm movement, reducing the risk of product damage. In some cases, air is used as a non-contact option to assist in product movement.

- Narrow-Edge Leading & Single-Filed – Ideal for sleeve cartoning and other packaging processes, Garvey’s equipment enables orientation with the narrow-edge leading in output.

Laning: Align products from a mass flow single source to single lanes feeding multiple upstream equipment.

Increased Efficiency: Reduces downtime and increases throughput, allowing for faster production cycles.

Versatility: Suitable for a wide range of products, from heat and eat mashed potatoes and mac and cheese to delicate bakery items like cupcakes, pastries and seasonal treats.

Durability: Built to withstand the rigors of industrial food production environments.

Industry Applications

Frozen Meals

Delicate Bakery Items

view our Case Studies.

and packaging videos.

Frequently Asked Questions

What types of food items can Garvey’s Cold Room solution handle?

Our solution is versatile and can handle a wide range of food items, including frozen meals, refrigerated trays, and delicate bakery items.

How does this solution improve efficiency?

By ensuring precise orientation and single-filing of food items, our solution reduces downtime and increases throughput, leading to faster production cycles.

Is Garvey’s solution compatible with existing packaging equipment?

Yes, our solution is designed to integrate seamlessly with most existing packaging equipment, making it easy to implement without significant modifications.

What are the maintenance requirements for Garvey’s Cold Room solution?

Our solution is built for durability and requires minimal maintenance, ensuring long-term reliability and performance.

Refrigerated & Frozen Food Production Solutions

Infinity™ Accumulation Tables

Bi-Flo™ Accumulation Tables