Contract Packaging

Accumulation Tables | Bi-Flo | Conveyors

With growing consumer demand for new products, food processors and manufacturers are under constant pressure to increase throughput. At the same time, strict regulation brings safety to the forefront of all processing initiatives. With a focus on sanitary design and first in, first out product flow, our accumulation tables and conveyors help contract packaging facilities and food processors reach their production goals without sacrificing safety.

Benefits of Garvey equipment

Increase throughput by up to 30%

Maximize line uptime by keeping your constraint running

Eliminate product and label damage with patented zero backpressure technology

Minimize maintenance costs

Shrink equipment footprint

Meet sustainability initiatives with lower energy use

Reduce noise

Contract Packaging Applications

From baked goods to packaged foods to condiments, whatever your product, our accumulation and conveying equipment can handle it. Here are just a few examples of food processing and packaging applications that use Garvey equipment.

Bagels

Bottled milk

Brownies

Dips

Frozen food trays

Frozen pizzas

Frozen sausage patties

Fruit cups

Granola bars

Pudding

Ready meals

Salad dressings

Sauces

Single-serve jelly

Snack pies and cakes

Yogurt cups

Bagels

Brownies

Frozen food trays

Frozen sausage patties

Granola bars

Ready meals

Sauces

Snack pies and cakes

Bottled milk

Dips

Frozen pizzas

Fruit cups

Pudding

Salad dressings

Single-serve jelly

Yogurt cups

To learn about these applications and more,

view our Case Studies.

and packaging videos.

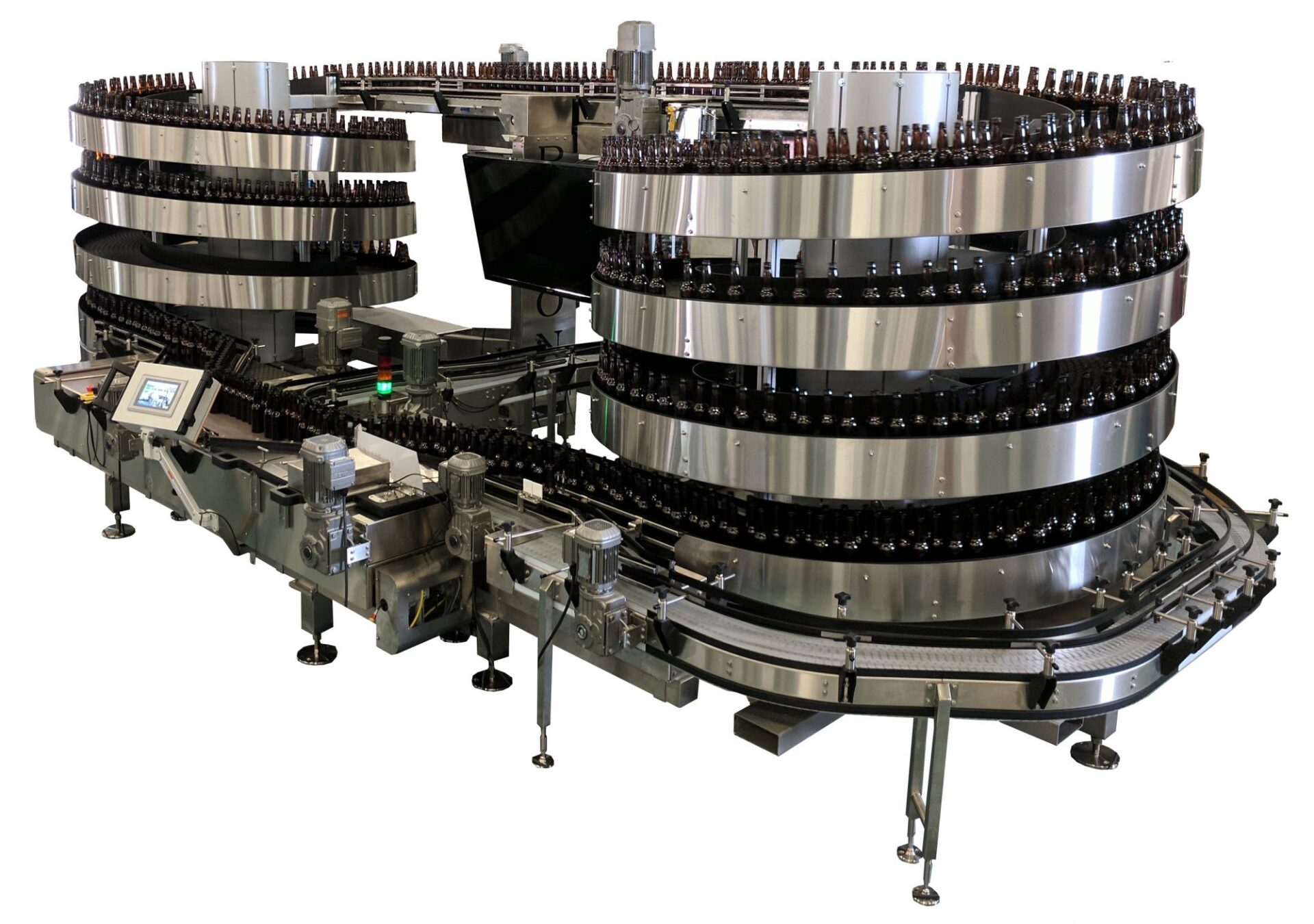

Accumulation and conveying equipment for food processing and packaging

Increase your throughput by up to 30% with our accumulation tables and conveyors designed for the food processing and contract packaging industry. Our patented technology can accumulate and single-file even the most unstable products at speeds unmatched in the industry.

Use our line efficiency calculator to determine how much more throughput you could be getting:

Food safety design features

Our standard solutions for food processing applications focus on sanitation and first in, first out product flow. Here are the key features of our standard equipment for the food industry, which provide easy cleaning:

We can also customize our equipment with additional features, such as angled cross channels, supports, and clean-out pockets, to meet enhanced food safety standards.

Chains that can be lifted out of the tracks

Open tracks so that debris falls straight to the floor

No hard-to-reach surfaces

Clean-out slots

All components specified for washdown duty

Accumulation tables

Infinity™ Accumulation Tables

Spiral Infinity™ Accumulation Tables

3D Infinity™ Accumulation Table

Bi-Flo™ Accumulation Tables

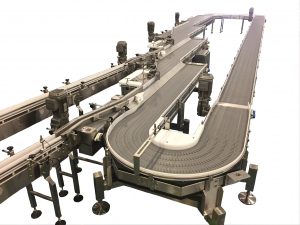

Conveyors

GT Series Table Top Conveyor

The GT series conveyor is Garvey’s latest innovative solution to your Table Top Conveyor System needs. The GT Series is designed to carry a wide variety of product at the widest variance of speeds.

Mat Top Conveyor

Mat Top Conveyor belts provide long life and high impact resistance. The Mat Top-style conveyors are perfect for almost all handling applications because the belt construction is ideal for easy cleaning and low maintenance.

6000 Series Raised Chain Conveyor

Garvey Corporation’s 6000 series “Raised Wearstrip” accumulation conveyors are designed to carry nearly any product and work well in nearly any application in the pharmaceutical, food, or cosmetic industry.

Interested in seeing how our equipment handles your products? Schedule an appointment to run your products in our testing facility. We now offer virtual demonstrations.

Custom accumulation and conveying equipment for food processing and contract packaging

Not sure what you need? Or looking for a custom solution? We’ve developed all of our accumulation tables and conveyors to meet the unique needs of processors and packages across many industries. If we don’t have a solution that meets your needs, get in touch. Our engineers will be happy to work with you to develop a customized solution for your application.