As the world moves towards a more sustainable future, electric vehicles (EVs) have emerged as a promising alternative to traditional gasoline-powered cars. Throughout 2022, many established automotive companies like Mercedes, Ford, and General Motors unveiled dozens of new electric vehicles.

The mass production of these vehicles is ramping up throughout 2023 and 2024. Cost is always a critical consideration in manufacturing, and economic pressure throughout North America, Europe, and China is making many automakers take a more stringent approach to their production.

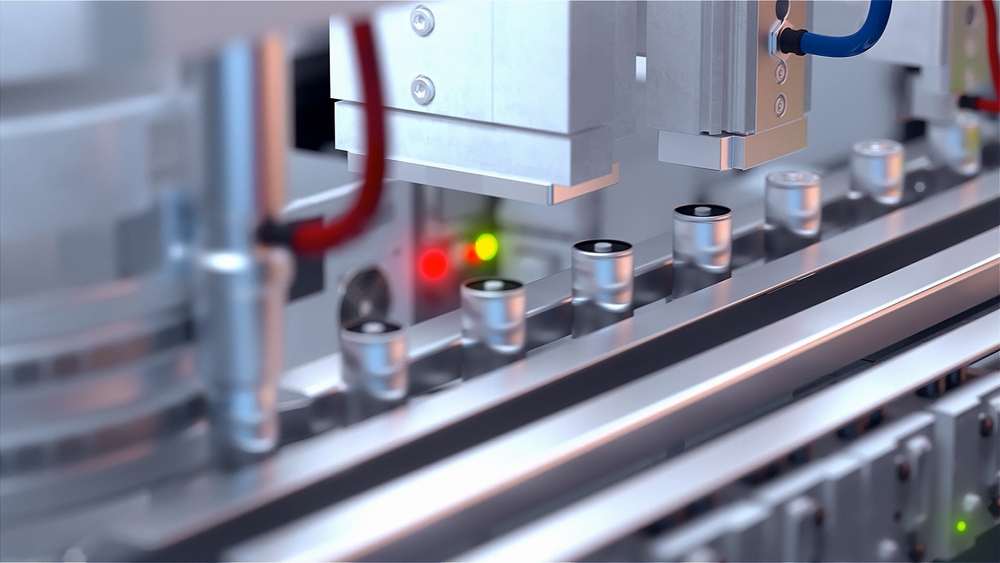

The production of EV batteries is a complex process that requires a high degree of precision. Streamlining production is one of the best ways to reduce production costs while increasing safety and product quality. Let’s look at how accumulation and conveyor systems can help improve the efficiency of EV battery production.

The Role of Efficiency in Production

Efficiency is critical because it directly affects the cost of production. The faster and more efficiently the production line runs, the lower the price per unit produced. In addition, an efficient production line can also help reduce waste, improve quality control, and increase throughput, which is especially important for EV producers who often work with limited amounts of highly valuable materials.

How Accumulation Systems Improve Efficiency

Accumulation systems are designed to help regulate the flow of materials on the production line. These systems temporarily store products or components at various points along the production line, allowing the line to continue running smoothly while the next step is being prepared.

In battery production, accumulation systems can help improve efficiency by reducing bottlenecks and minimizing downtime. For example, an accumulation system can store partially assembled battery cells while waiting for the final components to arrive. This helps keep the production line moving, even if one step in the process is delayed.

How Conveyor Systems Improve Efficiency

Conveyor systems are another key component in battery production. These systems use belts, rollers, and other mechanisms to transport materials from one point to another on the production line. Conveyor systems can be customized to fit the production line’s specific needs, with various speeds, sizes, and configurations available.

In battery production, conveyor systems can help improve efficiency by automating the movement of materials between production steps. This reduces the need for manual labor and minimizes the risk of errors or accidents. Conveyor systems can also be designed to work in tandem with accumulation systems, allowing materials to be stored and transported seamlessly throughout the production process.

Benefits of Using Garvey Equipment for EV Battery Production

The processes detailed above might sound familiar, but our team has taken accumulation and conveyor systems to the next level.

Creating Passive Paths

Traditionally, the production systems use a single file conveyor and metering systems to feed the multiple parallel machine centers. These production layouts often run like a traffic light system. There’s a lot of stopping and starting as diverters and logistics equipment moves products.

Our systems, in comparison, move like an interstate highway and create a production path past every machine. There are “exits” or outfeed guide work that can accept products whenever that specific machine requires it, lending to an efficient flow of products that reduces back pressure and potential damage.

This means no intervention is needed to get EV batteries to their destination. Enhancing how producers utilize accumulation and conveyor systems can allow multiple machines to operate simultaneously, creating the highest efficiency in the market.

Minimizing Downtime

Creating a more efficient line reduces downtime and the number of operators required to run the production line. Manufacturers can achieve the maximum output possible with their equipment by properly using accumulation and conveyors. Our equipment experts can help producers increase production by 15 to 30% and see cost reductions up to 5% to 15%.

Reducing Floor Layout Space

Accumulation and conveyor systems, by their very nature, are flexible in terms of layout. Whether a plant is redesigning its entire operation or wants to update a few pieces of equipment in a more traditional layout, accumulation and conveyor systems can be incorporated. For products where floor space is critical, there are suspended systems available that take up no floor space.

Keeping Up With EV Battery Production Demand

Increasing efficiency is key in any production plant, and the demand for EV parts continues to rise. Maximizing the capability of a production line using accumulation and conveyor equipment can allow manufacturers to increase production by 15-30% in the same facility. Discover how to improve your efficiency with the help of the experts. Contact us.