In 2025, the manufacturing industry is facing unprecedented challenges. From increased global demand to the pressures of maintaining efficiency amid supply chain disruptions, manufacturers are navigating a rapidly evolving landscape. At the heart of solving these challenges lies an often underappreciated hero: the accumulation system. These systems play a pivotal role in keeping production lines running smoothly, maximizing throughput, and ensuring consistent product quality.

Here’s why accumulation systems are more critical than ever in 2025 and how they’re shaping the future of manufacturing.

The Evolving Manufacturing Landscape

Manufacturers today are under intense pressure to adapt to a new set of demands:

- Rising Throughput Requirements: Global demand for goods is expected to increase by 15% in 2025, pushing production lines to operate faster and more efficiently than ever before.

- Supply Chain Volatility: Ongoing disruptions require production lines to be more adaptable, with minimal downtime to maintain output.

- Smart Manufacturing: Industry 4.0 practices are driving the integration of intelligent, automated solutions to optimize operations and minimize waste.

- Sustainability Goals: Manufacturers are under greater scrutiny to reduce energy consumption and product loss, making operational efficiency a top priority.

Accumulation systems are uniquely positioned to address these challenges by maintaining consistent flow and minimizing the impact of slowdowns or stoppages.

The Role of Accumulation Systems in Modern Production

Accumulation systems act as the backbone of efficient production lines, ensuring that no single machine bottleneck disrupts overall operations. Here’s how they work:

- Buffering to Prevent Downtime: Accumulation systems create a buffer that absorbs disruptions, keeping upstream and downstream machines running even when one machine slows or stops.

- Pressureless Handling: Garvey’s patented pressureless technology minimizes product damage, especially for fragile or irregularly shaped items like glass bottles or thin-walled containers.

- Optimized Flow: By maintaining consistent product flow, accumulation systems ensure that lines operate at maximum efficiency, reducing waste and downtime.

Real-World Applications of Accumulation Systems

Accumulation systems deliver measurable benefits across a range of industries:

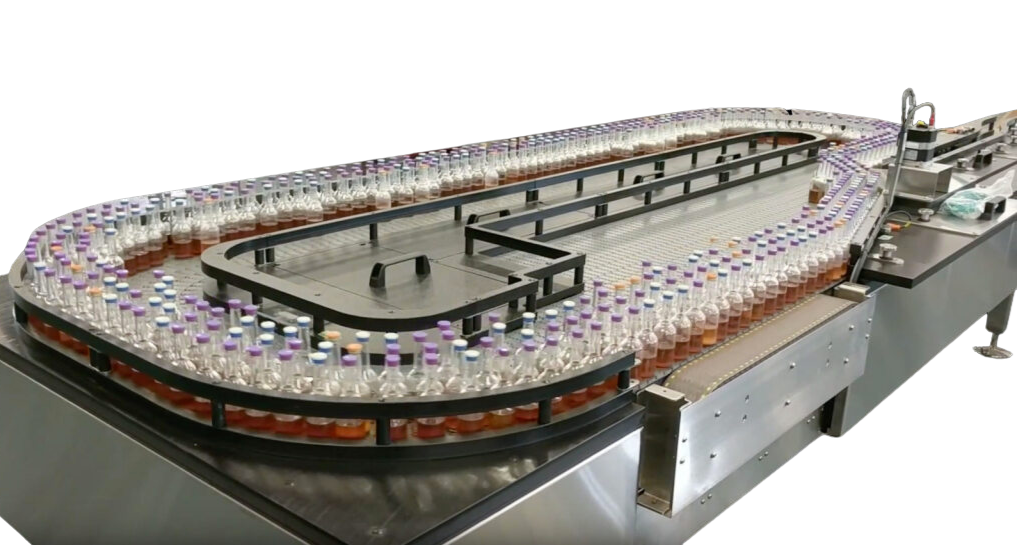

Pharmaceuticals

In pharmaceutical manufacturing, the handling of fragile vials and syringes requires precision and care. Accumulation systems ensure these items are processed smoothly, minimizing breakage and protecting product integrity.

Food & Beverage

The food and beverage industry often deals with irregularly shaped containers, such as reverse-tapered bottles or cans. Accumulation systems prevent tipping and label damage, ensuring products move seamlessly through filling, capping, and labeling processes.

Personal Care

High-speed production lines for personal care products rely on accumulation systems to maintain product integrity and flow during machine slowdowns, ensuring consistent throughput and quality.

Why Accumulation Systems Matter More in 2025

The manufacturing challenges of 2025 make accumulation systems indispensable:

- Adapting to Smart Manufacturing: As more manufacturers adopt Industry 4.0 practices, accumulation systems provide the flexibility and integration needed for automated, intelligent production lines.

- Addressing Sustainability Goals: By reducing product waste and energy consumption, accumulation systems help manufacturers meet sustainability targets while improving profitability.

- Handling Increased Customization: With rising demand for customized products, accumulation systems enable quick product changeovers without disrupting line efficiency.

- Supporting Higher Speeds: Modern accumulation systems can handle high-speed production lines without compromising product integrity, ensuring manufacturers meet market demands.

Ready to Optimize Your Line for 2025?

Accumulation systems are no longer optional—they’re essential for staying competitive in today’s manufacturing environment. By integrating these systems into your production line, you can boost efficiency, reduce downtime, and achieve higher throughput.

At Garvey Corporation, we specialize in advanced accumulation solutions tailored to your industry’s unique needs. Don’t let bottlenecks hold your line back.

Schedule a free Line Analysis today and discover how Garvey’s accumulation systems can revolutionize your operations in 2025.