Wine Bottles

Customer’s Challenge

Customer was looking to improve efficiency of line.

Product Specifications

Product --------- Full Glass Wine Bottles

Size

750 ml

Shape

Straight Wall, Tapered Wall, Reverse Tapered Wall

Diameter

2.829″ (min) to 3.484″ (max)

Height

11.438″ (min) to 13″ (max)

Weight

2.8 lbs (min) to 3.2 lbs (max)

Rate In

375 BPM

Rate Out

400 BPM

Description of Function

By performing a Line Analysis Test, we are able to determine the constraint as the Monoblock, a Rinser/Filler/Capper/Corker machine. In order improve the efficiency of a line we must keep the constraint, or in this case the Monoblock, running as often as possible. By integrating an Infinity™ Style Accumulator between the Monoblock and the Capsuler it will act as a buffer for products that will decrease unnecessary downtime on the Monoblock, ultimately improving the productivity. Our G7 Infinity™ Style Accumulator #1 will accumulate a capacity of 1,935 bottles at 2.839” ø for 4.8 minutes and 1,270 bottles at 3.484” ø for 3.2 minutes. Products will enter the table in single file and depending on the condition of the line bottles will either accumulate keeping the Monoblock running and alleviating any downtime or exit bottles through the outfeed lane. The outfeed lane will convey products double-row-nested and will single file products through a pressure combiner to feed the customers Capsuler.

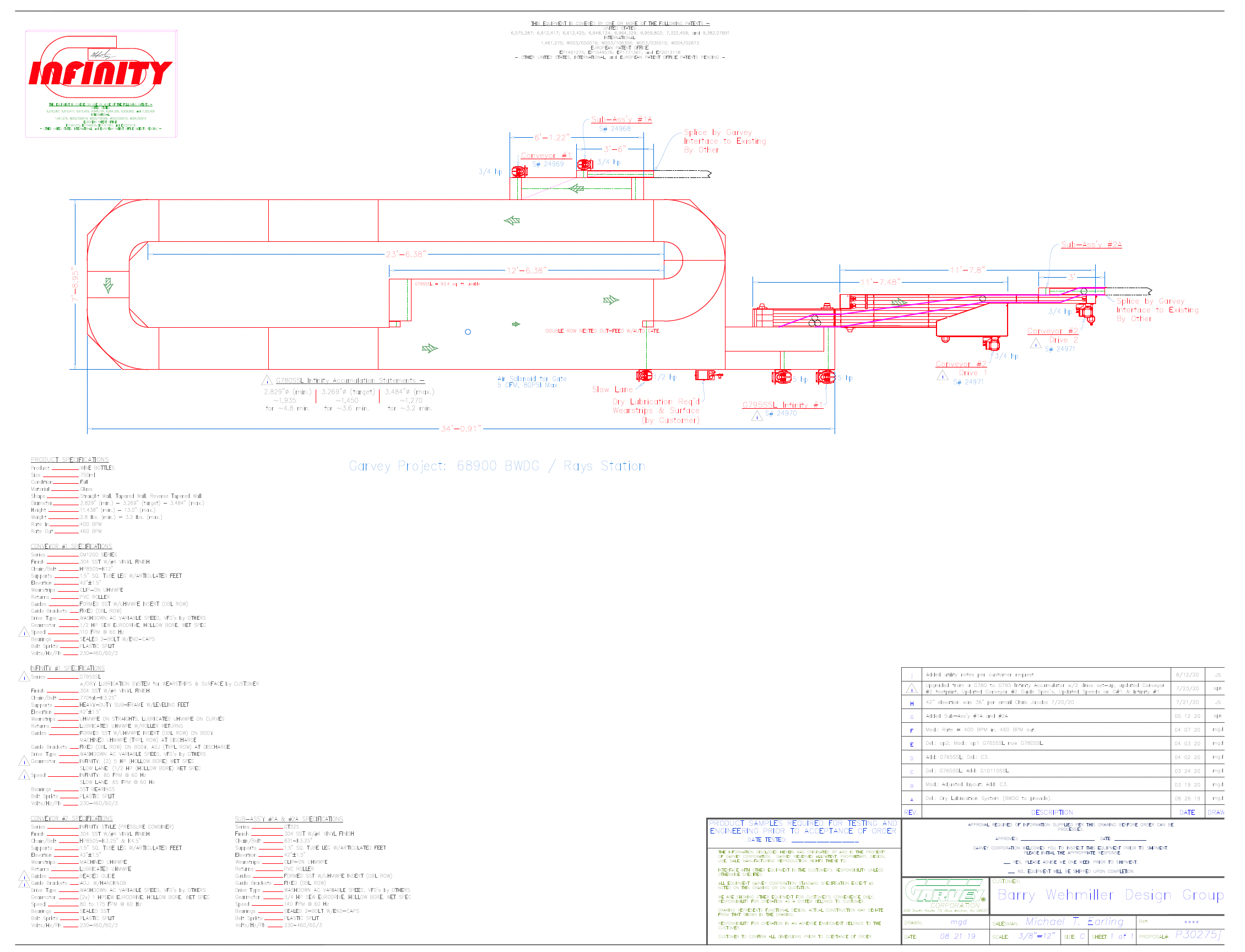

Drawing for Project

U.S. Patent # 6,575,287; 6,612,425; 6,612,417; 6,648,124; 6,959,802; 6,964,329; & 7,322,459 –

International Patent # 1,461,275; 2004/4385; 2004/3144; 2003257101; 2003237267; 2002337898 & 2002366575

Other US & International Patents Pending

International Patent # 1,461,275; 2004/4385; 2004/3144; 2003257101; 2003237267; 2002337898 & 2002366575

Other US & International Patents Pending