Applesauce Cups

Customer’s Challenge

The customer wanted to increase the overall throughput of their line and decrease the chance of backup through the filler.

Product Specifications

Product --------- Tapered Round Polypropylene Cups

Size

4 oz.

4.5 oz.

Diameter Above

2.953″

2.953″

Diameter Below

2″

2″

Height

1.6″

1.787″

Weight

4.5 oz.

4.5 oz.

Infeed Rate

390 CPM

Outfeed Rate

425 CPM (225 CPM per lane)

Description of Function

By performing a Line Analysis, it was determined that the Constraint within the line is the Filler. Garveys G7 Series Infinity™ Style Accumulator is able to accumulate a capacity of 1,400 cups at 2.953” ø for approx. 3.8 minutes. Products will flow from the Filler to the Rinsing machine and transfer onto the Infinity™ Table #1 en masse. Cups will enter onto the Table at 390 cpm and depending on the condition of the line will either accumulate, relieving backup through the Rinsing and Filling Machines, or convey through to the Packing Machine. By integrating one of our accumulation machines between the Filler and Packer it will allow the Filler to continue production if the Packaging Machine were to shut down. By keeping the constraint running this will decrease downtime and will increase product throughput.

An issue that was observed during testing occurred whenever products would back up, due to the nature of their design, the cups would start to shingle affecting flow and accumulation. Garvey resolved this issue by adding Polycarbonate Hold-Down Covers to the areas in question. This relieved the issue of shingling allowing for a smoother product flow.

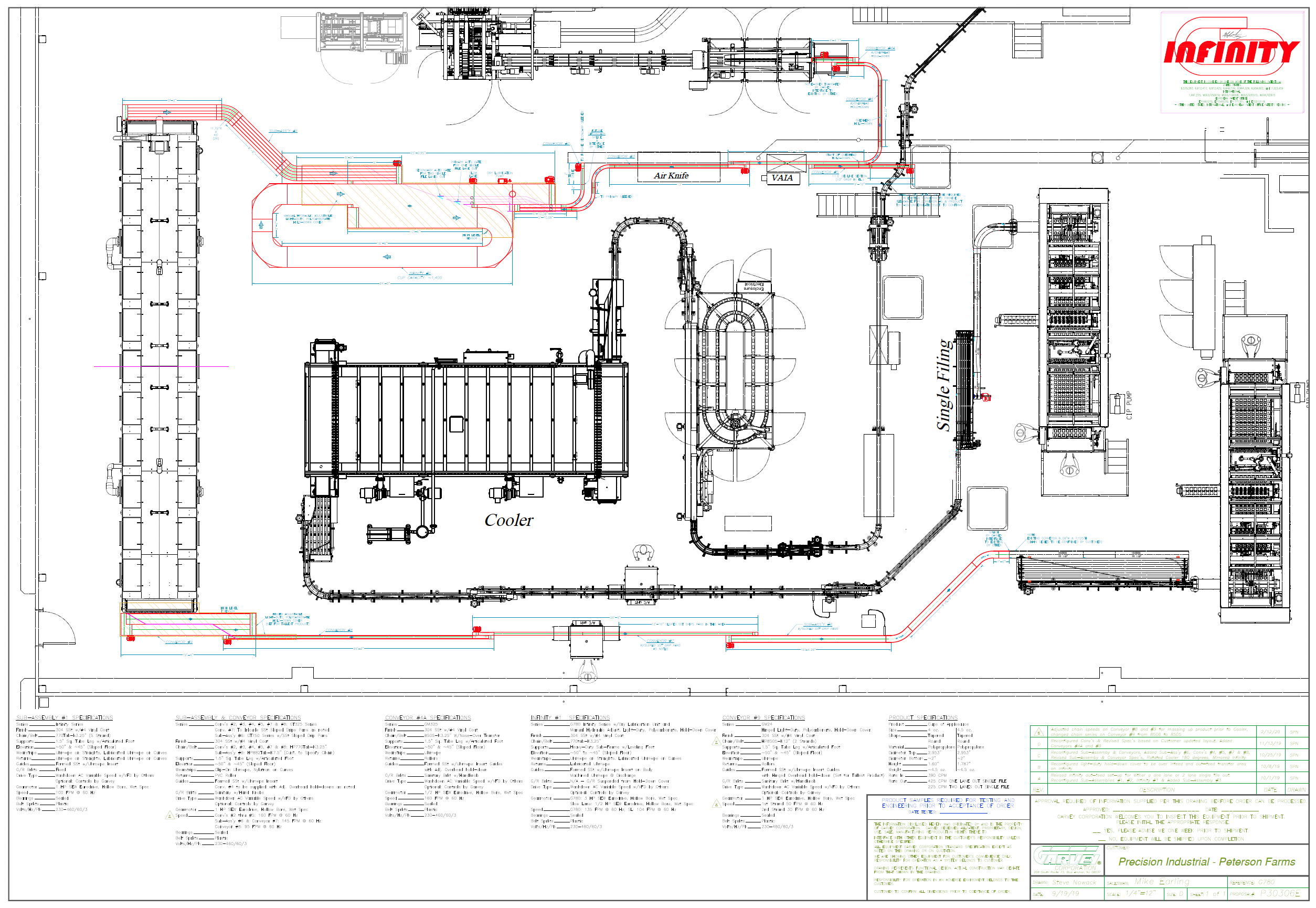

Drawing for Project

U.S. Patent # 6,575,287; 6,612,425; 6,612,417; 6,648,124; 6,959,802; 6,964,329; & 7,322,459 –

International Patent # 1,461,275; 2004/4385; 2004/3144; 2003257101; 2003237267; 2002337898 & 2002366575

Other US & International Patents Pending

International Patent # 1,461,275; 2004/4385; 2004/3144; 2003257101; 2003237267; 2002337898 & 2002366575

Other US & International Patents Pending