Table Top Conveyor Solutions

Precision Handling & Zero-Pressure Transport from Garvey

Are production line inefficiencies limiting your throughput?

Discover How Garvey's Table Top Conveyor Solutions Can Transform Your Manufacturing Process.

Imagine a production line where products flow seamlessly from start to finish, with precise handling and zero pressure damage. From delicate glass vials to heavy containers, from round bottles to rectangular cartons, our table top conveyor systems ensure flawless product transport at every stage of your operation.

Whether you need FDA-compliant sanitary design for food processing or robust industrial solutions for high-speed packaging, we can handle it. Our nearly century-long legacy of innovation means one thing: when standard conveyors fail, Garvey delivers.

Why Choose Garvey Table Top Conveyors?

Our patented conveyor technology delivers what standard table top systems can’t:

Precision Product Handling

- Zero-pressure transport eliminates product and label damage

- Handles any shape – from round bottles to rectangular cartons

- Maintains perfect product orientation

Advanced Line Integration

- Seamless integration with existing equipment

- Multiple configurations for 90° and 180° transfers

- Custom solutions for unique space requirements

Industry-Leading Support

- Free in-house product testing

- Complete line analysis

- Expert technical support

Sanitary Design Standards

- Stainless steel construction for washdown environments

- Tool-free maintenance access

- FDA and USDA compliant design

Proven Experience

- Nearly 100 years of conveyor innovation

- Trusted by leading manufacturers worldwide

- Multiple patents and ongoing R&D

Explore Our Range of Table Top Conveyors

9600 Series Table Top Conveyor

The 9600 series is Garvey’s standard solution for table top conveying needs, designed to handle diverse products at varying speeds. Its modular construction allows for quick line design and modifications. By selecting components that match your specific conveying requirements, our engineers can rapidly provide an exact solution tailored to your needs. Perfect for operations requiring flexible product handling, the 9600 series ensures reliable performance while maintaining line efficiency.

AquaGard GT Series Conveyor

The AquaGard GT represents the first collaborative product between Garvey and Dorner, combining our GT series excellence with Dorner’s AquaGard 7100 sanitary stainless steel design. This innovative system seamlessly integrates with accumulation systems and other machinery, creating fully automated processing lines ideal for bottling, canning, and food processing applications. Its modular design enables quick customization and efficient line modifications, making it perfect for operations requiring sanitary handling and maximum flexibility.

Take the Next Step in Optimizing Your Production Line

Accumulation Tables

Conveyors

Garvey conveyors include the 6000 Series, 9600 Series, Clean Room Transfer and the Gap Transfer, portable conveyors, standard conveyors and raised wearstrip conveyors.

Handling Devices

Garvey’s handling devices for conveyors include the Gripper Elevator conveyor elevator for conveyors.

Pharmaceutical

Garvey Corporation products that maximize pharmaceutical industry line efficiency, patented technologies include Automatic Tray Loader and Automatic Vial Dryer.

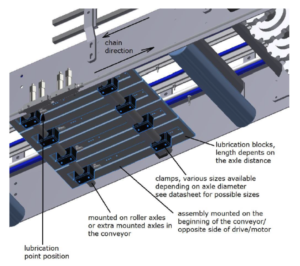

Garvey Lubrication System

Corner lubrication is done the same way it was done using the Lincoln pumps. The UHMWPE blocks do not push on the chain – it contacts the blocks via catenary sag and leads into the return tracks.

Distribution Systems

Why complicate your line with a traditional metering system when you can simplify it and make it more efficient with an on-demand distribution system?