Pharmaceutical

Tray Loaders | Vial Dryers | Accumulation Tables | Conveyors | Distribution Systems

When it comes to efficient processing, pharmaceutical manufacturers face three major issues: fragile products, pressure to reduce processing time, and strict regulations. Whether your product is packaged in glass vials, pill containers, or medicine bottles, our solutions can streamline your products through your production line with minimal yield loss. Our first-in-first-out product flow ensures product integrity and reduces product time on the line. These processes can automatically load vials into trays at over 1,000 vials per minute and in some cases reduce vial drying time from 48 hours to 5 minutes.

Benefits of Garvey equipment

Increase throughput by up to 30%

Maximize line uptime by keeping your constraint running

Eliminate product and label damage with patented zero backpressure technology

Minimize maintenance costs

Shrink equipment footprint

Meet sustainability initiatives with lower energy use

Reduce noise

Pharmaceutical and nutraceutical applications

From standard pill bottles to vials containing liquid or lyophilized drugs, whatever your product, our equipment can handle it. Here are just a few examples of pharmaceutical and nutraceutical applications that use Garvey equipment.

CBD Products

Prescription Drug Bottles

Vaccines

Vials Containing Liquid or Lyophilized Drugs

Vitamins and Supplements

CBD Products

Vaccines

Prescription Drug Bottles

Vials Containing Liquid or Lyophilized Drugs

Vitamins and Supplements

To learn about these applications and more,

view our Case Studies.

and nutraceutical videos.

Cleanroom design features

Our standard solutions for pharmaceutical applications focus on sanitation and first in, first out product flow. Here are the key features of our standard equipment for the pharma industry, which provide easy cleaning:

We can also customize our equipment with additional features, such as angled cross channels, supports, and clean-out pockets, to meet enhanced safety standards.

Chains that can be lifted out of the tracks

Open tracks so that debris falls straight to the floor

No hard-to-reach surfaces

Clean-out slots

All components specified for washdown duty

Accumulation, vial drying, and distribution equipment for pharmaceutical and nutraceutical applications

Increase your throughput by up to 30%, decrease vial drying time, and facilitate product inspection with our solutions designed for industrial applications. Our patented technology can accumulate, single-file, and distribute even the most unstable products at speeds unmatched in the industry.

Use our line efficiency calculator to determine how much more throughput you could be getting:

Vial handling systems

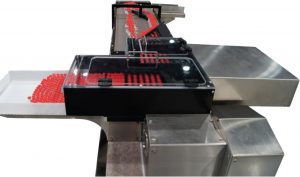

Automatic Tray Loader

This revolutionary design of this pharmaceutical conveyor can load up to 800 3ml vpm into cardboard or plastic trays with extremely low vial to vial impact.

Garvey Automatic Vial Dryer

This revolutionary vial drying system dries products of all sizes in mere minutes far surpassing the industry standard. This full system also utilizes our patented Infinity Accumulation System to outfeed vials at unprecedented speeds in the industry.

Accumulation systems

Infinity™ RX Accumulation Table

Infinity™ RX Rotary Replacement Models

This tabletop accumulator was developed to be a simple and effective replacement for rotary table or turntable accumulators. The patented Infinity™ RX 36”, 48” and 60″ can out-feed products faster than a traditional rotary table and with less pressure.

Conveyors

Rx Conveyor

The Rx design implements a proactive approach to increase cleanliness, minimizing dirt pockets and maximizing rounded surfaces for better drainage. The Garvey conveyor system includes a complete range of guide rails and supports.

6000 Series Raised Chain Conveyor

Garvey Corporation’s 6000 series “Raised Wearstrip” accumulation conveyors are designed to carry nearly any product and work well in nearly any application in the pharmaceutical, food, or cosmetic industry.

Clean Room Transfer

The Garvey Clean Room Transfer is clean pass through conveyor designed to minimize the size of the exit portal of a clean room while providing a flush chain to chain transfer, eliminating the need for a dead plate.

Distribution systems

Do you need to transfer filled bottles from a mass flow to parallel inspection or labeling stations? In a traditional metering system, bottles have to stop at every machine. With our on-demand distribution systems, products circle continuously until they encounter an empty machine, guaranteeing that no machine capable of working is ever sitting idle. Learn More

Interested in seeing how our equipment handles your products? Schedule an appointment to run your products in our testing facility. We now offer virtual demonstrations.

Custom accumulation and conveying equipment for pharmaceutical and nutraceutical applications

Not sure what you need? Or looking for a custom solution? We’ve developed all of our accumulation tables and conveyors to meet the unique needs of processors and packages across many industries. If we don’t have a solution that meets your needs, get in touch. Our engineers will be happy to work with you to develop a customized solution for your application.