Meeting customer demand is critical to a successful business. Recently, a vintner came to us with a dilemma: they needed to increase their production of unique wine bottles. Before creating a solution, we needed to understand more about their production practices and goals.

Wine Production Bottling and Packaging

Wine bottles are generally made from glass and tapered in shape. The vintners had a unique shaped bottle shaped like a glass tube or vial. This vial is very tall and unstable.

To compensate for the irregular shape, the winemaker bottled the vials by hand. The production line would fill the long bottles one by one under the filler before screwing the cap on. While this filled the bottles securely, it only produced about 12 to 15 bottles a minute.

Scaling Up Production with Automation

Our accumulation experts reviewed the vintners bottling process and devised a way to increase their production significantly. We aimed to get the bottles filled and packaged with as little disruption as possible.

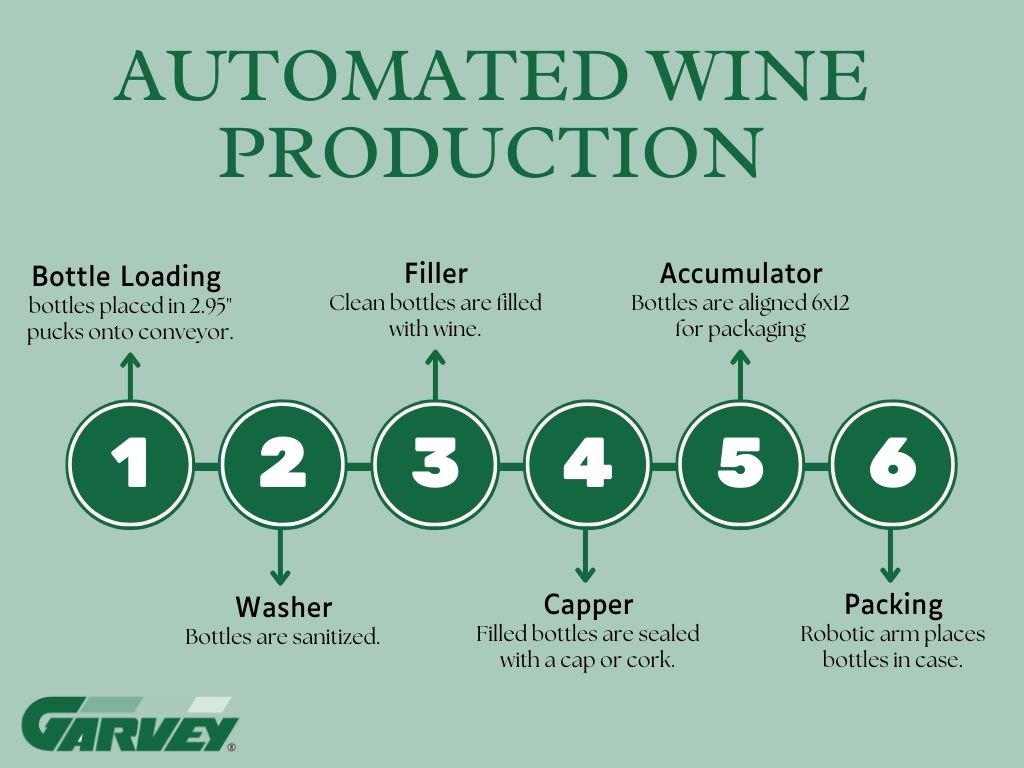

Here are the step-by-step wine bottling process and improvements we devised:

Vial Loading

Instead of holding, filling, and capping each bottle by hand, wine vials are loaded onto a conveyor. Each vial is inserted into an empty 2.95” puck that holds the glass upright securely. Inserting the vials into the empty pucks is the only part of the bottling process done by hand.

Washer

Once inserted into the puck, the vials are on the move. They first head to the washer for sanitization.

Filler

The next stop is the filler. At this stage, each vial is filled with wine.

Capper

Once full, the vials head to the next stop to the capper.

Accumulator

So far, this process has probably sounded reasonably standard. After being sealed, the vials go to an accumulator, which is one of the biggest differentiators. Not only buffers the line equipment from stoppages but also lanes the product into 6 lanes. The accumulator then uses a shuttle system to build an array of products in a dedicated pick zone for the Robotic case packer to pick off the system. The accumulator aligns all the pucks holding vials into position to be packaged, automatically creating alignments 6 vials wide by 12 vials deep.

Packing

Our team worked with a robotics company, BCS Motion, to improve the packaging process. Once all the bottles are aligned, a robotic arm suctions up the 6×12 array of bottles (or 72 bottles in total). The machine then rotates and carefully releases the bottles into a funnel that drops down into a case for packaging. The case is sealed and is ready for shipment.

Using this method of production, the vintner dramatically increased their production. They now produce 100 vials per minute—a production increase of 566.66%!

Line Analysis and Increasing Production

Every manufacturer has its own approach to production. We work with food processing, beverage, personal care, pharmaceutical, and industrial companies to augment their production practices through accumulation. However, we can also utilize our expertise and partnerships to help manufacturers implement additional robotics improvements in their production that merge with our technology.

If you want to increase your production, having an accumulation expert review your current process is the best way. Contact us to get started.