In the world of pharmaceutical manufacturing, precision isn’t just a goal—it’s a necessity. Every vial that rolls off the line carries not just medicine, but the weight of regulatory compliance, patient safety, and operational efficiency. And behind the scenes, companies like Garvey are quietly transforming how these vials move, pause, and progress through the production line.

Let’s take a walk through a modern pharmaceutical vial operation and see how Garvey’s accumulation solutions bring order, speed, and reliability to every step.

Step 1: The Journey Begins – Vial Fillers

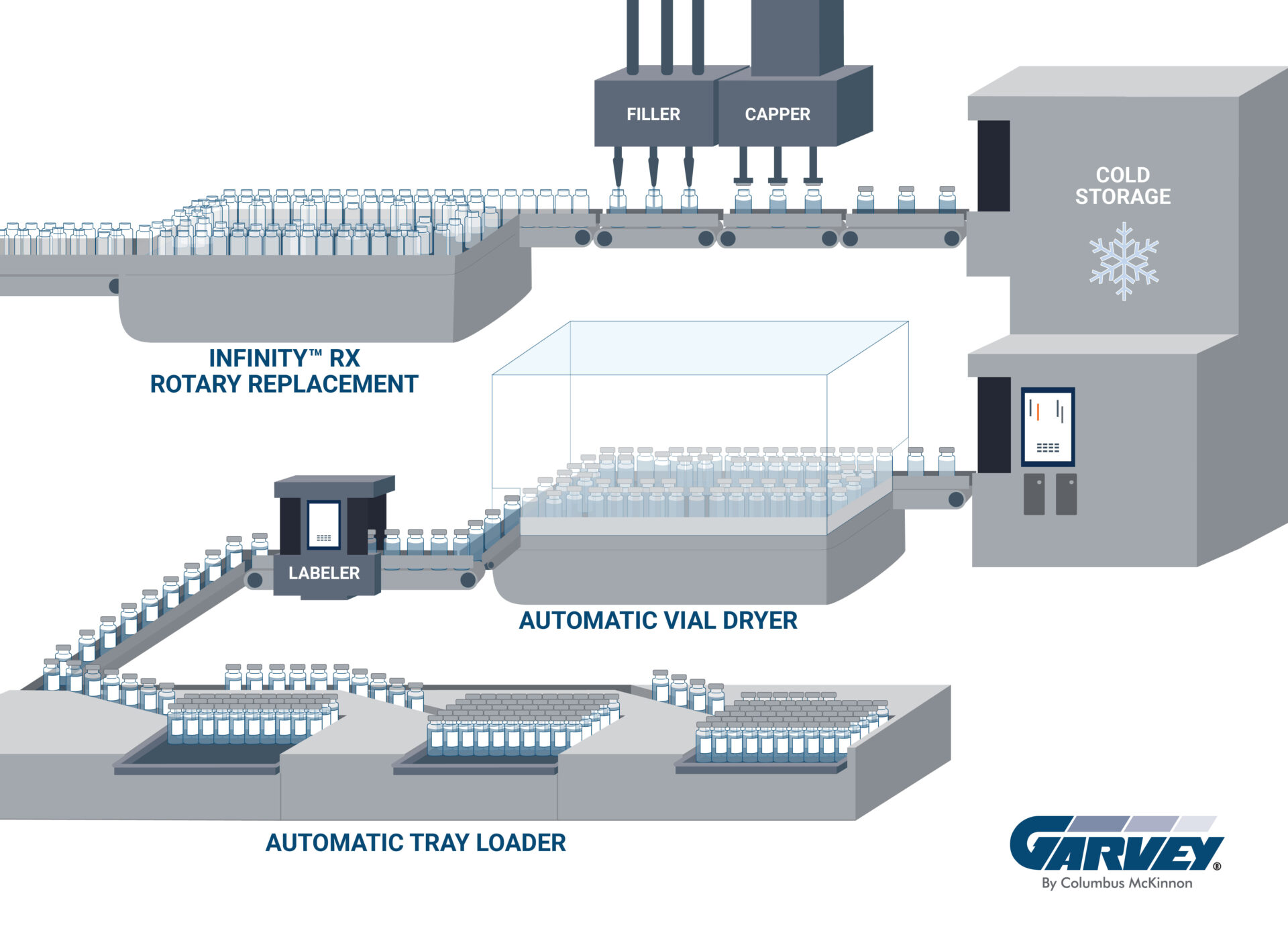

It all starts with empty vials—thousands of them. Traditionally, these vials would be loaded onto a rotary table, a method that often led to jams, breakage, and inconsistent flow. Garvey’s RX Rotary Replacement changes the game. This system gently guides vials into a single file, preparing them for the filling station with minimal pressure and maximum control.

The result? A smoother start to the line, fewer stoppages, and a significant reduction in product loss. It’s a small change with a big impact—setting the tone for the rest of the operation.

Step 2: Into the Cold – Cold Storage Integration

Once filled, many vials head straight into cold storage. This is where temperature-sensitive medications are preserved, but it’s also where condensation becomes a hidden enemy. While Garvey doesn’t make cold storage units, their systems are designed to integrate seamlessly with them. The transition from cold storage to the next phase is where Garvey’s engineering precision really shines.

Step 3: The Unsung Hero – Automatic Vial Dryer

Imagine pulling a cold soda can out of the fridge on a humid day. That same condensation happens to vials—and it’s a nightmare for labeling. Enter Garvey’s Automatic Vial Dryer.

This isn’t just a fan blowing air. It’s a patented system that uses accumulation technology to gently dry vials in minutes, not hours. By the time the vials reach the labeler, they’re dry, clean, and ready. No smudged labels. No rework. Just a clean handoff to the next step.

Step 4: Precision in Motion – Labeling

Labeling is more than just a sticker—it’s traceability, compliance, and branding all in one. Thanks to Garvey’s single-filing systems, vials arrive at the labeler perfectly spaced and oriented. This precision ensures that every label is applied exactly where it should be, every time.

Step 5: The Heartbeat of the Line – Infinity RX Accumulation Table

If the production line is a living organism, the Infinity RX Accumulation Table is its heartbeat. This system doesn’t just hold vials—it manages flow, absorbs disruptions, and keeps everything moving.

Designed specifically for fragile pharmaceutical containers, the Infinity RX can handle over 800 vials per minute without pressure buildup. It’s FDA-compliant, clean-in-place ready, and built to keep the line running even when downstream equipment slows or stops. In short, it’s the buffer that keeps chaos at bay.

Step 6: The Final Touch – Tray Loading

At the end of the line, vials need to be packed for transport or storage. Garvey’s Automatic Tray Loader does this with the same care and speed seen throughout the process. Vials are gently placed into trays with minimal contact, preserving their integrity and ensuring they’re ready for the next leg of their journey.

A Seamless Fit for a Complex Process

Garvey’s accumulation products aren’t just machines—they’re problem solvers. They address the hidden inefficiencies, the fragile moments, and the pressure points in pharmaceutical vial operations. From the first empty vial to the final packed tray, Garvey ensures that every step is faster, safer, and more reliable.