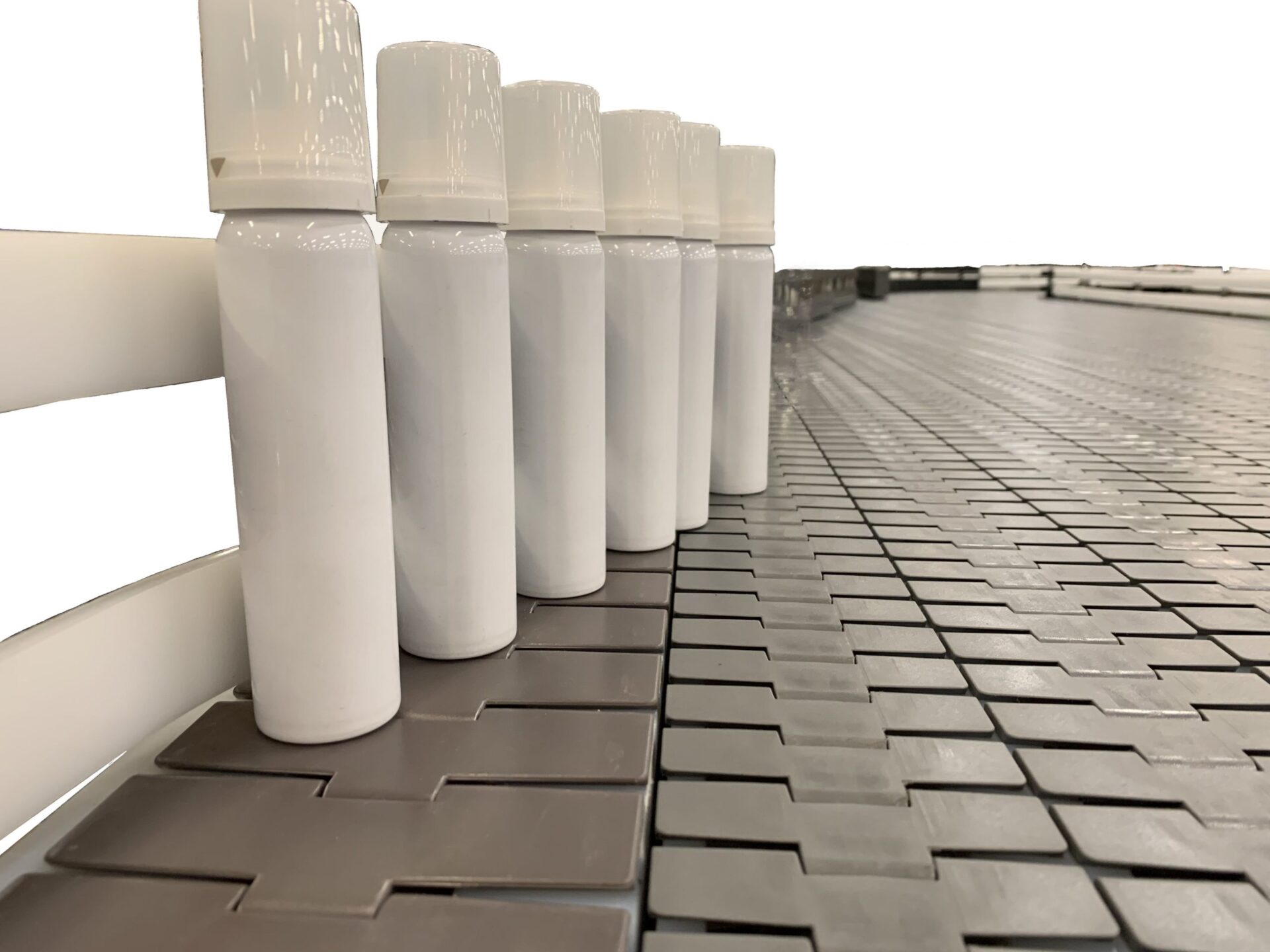

Garvey’s unique conveyor design provides maximum stability for even the most challenging products, allowing manufacturers to increase line speeds with confidence

BLUE ANCHOR, N.J. (PRWEB) JANUARY 24, 2020

Product stability is one of the biggest production line challenges manufacturers face. This is true whether those lines are running lightweight products such as small plastic vials or heavy ones like wine bottles. As line speeds increase, keeping products upright becomes even more crucial, because, if one unit falls over, it can create a domino effect. On high-speed lines, fallen products are a significant source of unnecessary downtime and labor demands.

What many manufacturers may not realize is that these stability issues are caused by the design of the conveyor systems. Specifically, they’re caused by dead plates.

“A dead plate is a stationary flat surface, typically a piece of metal or plastic, between two conveyors,” explains Mike Earling, Vice President of Sales at Garvey Corporation. “Since the dead plate doesn’t move, the product has to slide over it to get to the next conveyor. But most of the time it doesn’t slide — another product has to come down the line and push it off of the dead plate. The faster you go, the bigger the collision, and these collisions can cause the product to fall over.”

Fallen products don’t just necessitate shutting down the line. They increase labor requirements, because workers must manually stand the products back up again. They can also damage fragile products, such as causing microfractures in glass vials.

That’s why Garvey designs all of its conveyors without dead plates.

“The reason most conveyor systems have dead plates is because the bearings and motors driving the conveyors are mounted on the outside of the equipment,” says Thomas Garvey, the company’s president. “We put the bearings and motors inside the equipment frame, which allows the conveyors to lie flush against each other, promoting a smooth side transfer. This design feature makes Garvey conveyors the best in the world at handling unstable products.”

Dead plates are common, but you can achieve a stronger, more stable production line without them. Contact the Garvey team to learn more about how their industry-leading conveyor design can help you maximize throughput by improving product handling in your facility.

About Garvey

For nearly 100 years, Garvey Corporation has been a leader in producing conveying, accumulating, and automation solutions that can help manufacturers increase throughput by up to 30%. Garvey’s line of solutions includes cutting-edge accumulation tables, rotary tables, conveyors, and more essentials to make your production lines more efficient. Visit Garvey online or follow the company on social media: Facebook, Twitter, YouTube, LinkedIn.