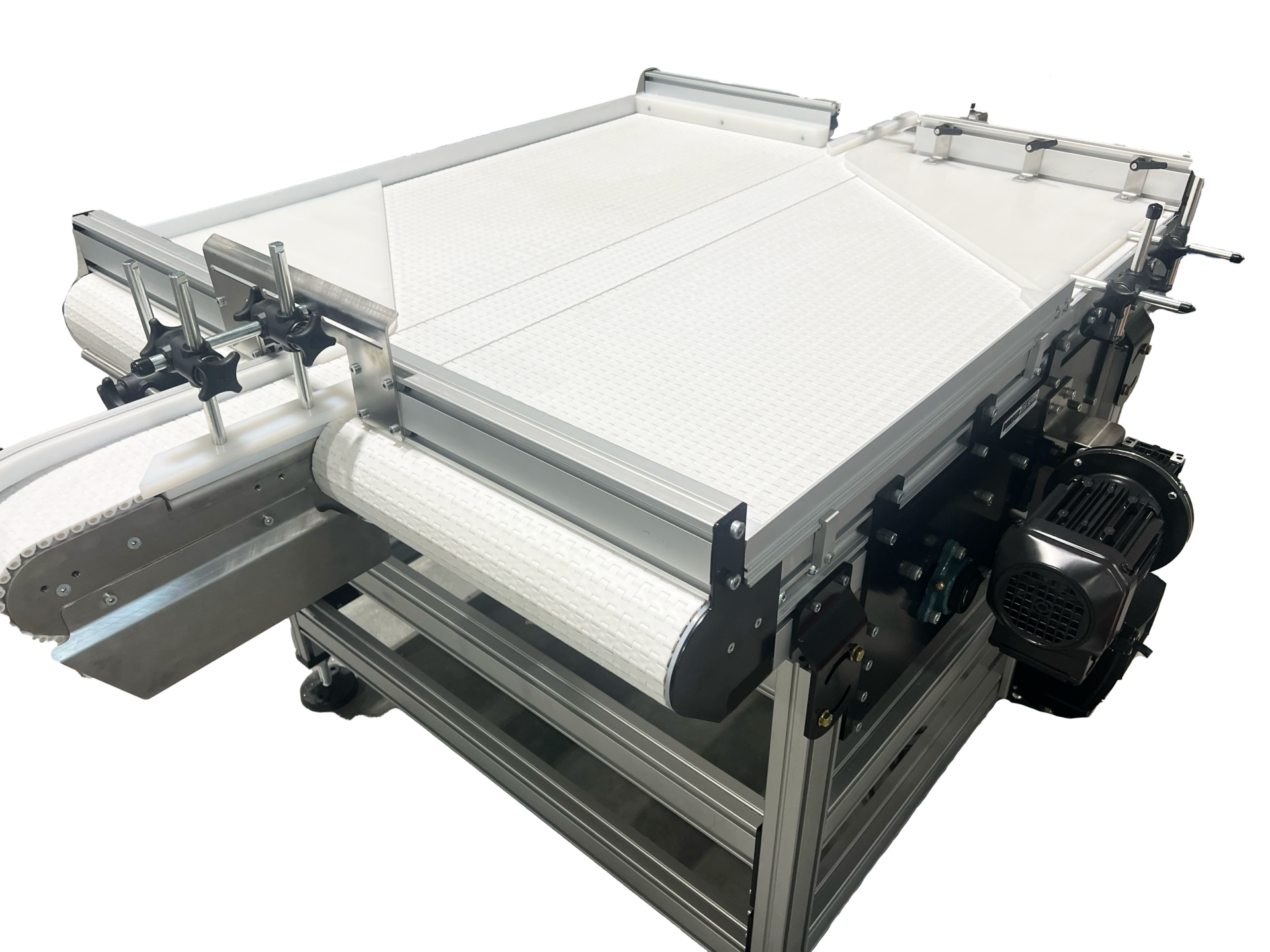

Aluminum Bi-Flo™ Accumulation Table

Features & Benefits

- Compact & Efficient Design: A single motor drives three modular chain sets in different directions, enabling product recirculation in a small footprint. The design is simple, robust, energy-efficient, and easy to integrate into existing lines.

- Optimized Product Transfer: Flush side in/outfeeds enable stable side transfers. Optional nosebar configurations are available for tight spaces.

- Customizable Dimension: Width and length can be tailored to fit available space and accumulation needs.

- Flexible Motor Placement: Motor can be mounted on either side for easier integration

- Controlled Flow: Optional manual or automatic gates manage infeed and outfeed flow.

- Durable & Lightweight Construction: Aluminum frame offers high load capacity with cost-effective rigidity.

- Multi-Line Integration: Supports multiple infeed/outfeed setups to merge or split product flow across lines.

- Versatile Product Handling: Compatible with round, oval, and rectangular products.

- Safe Operation: Pinch-free design ensures safe manual interaction near or on the table.

Specifications

- Feed maximum chain speed: 100ft/min.

- Product sizes range: 1.25 in. to 10 in. diameter or length.

- Table maximum load capacity: 500lbs. *Actual load is dependent on belt speed.

- Top of chain height range: 20 in. to 60 in.

- Fully adjustable guides, easily adjustable in the field to promote maximum flexibility.

Increase Efficiency

Boost Productivity

Maximize Line Uptime

Keep Constraint Running

Eliminate Backpressure

Multi-Functional

Single File

Lane Divide

On Demand Flow Divide

Lean Manufacturing

Lower Motor Count

Minimize Energy Use

Reduce Space Requirements

Minimize Friction & Noise

Simple Design

Minimize Maintenance Costs

Best Return On Investment

Proven Industry Results

Lowest Operation Costs

Zero-Pressure Accumulation

Configuration Options

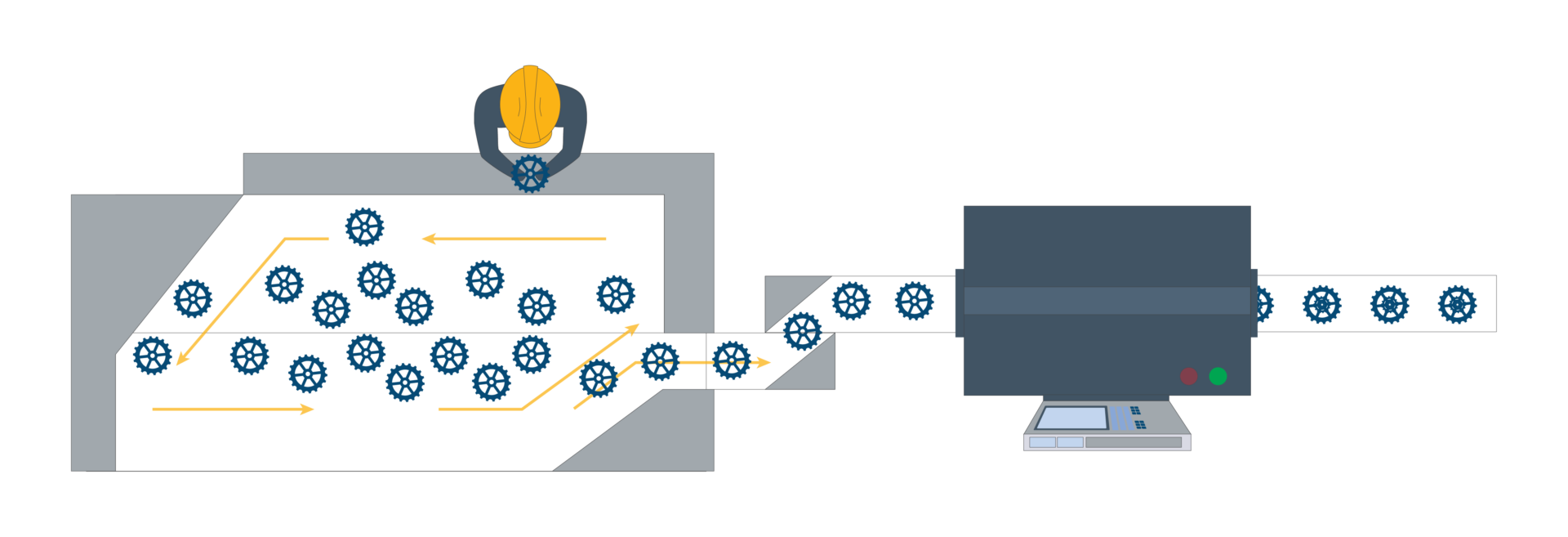

One Outfeed Lane:

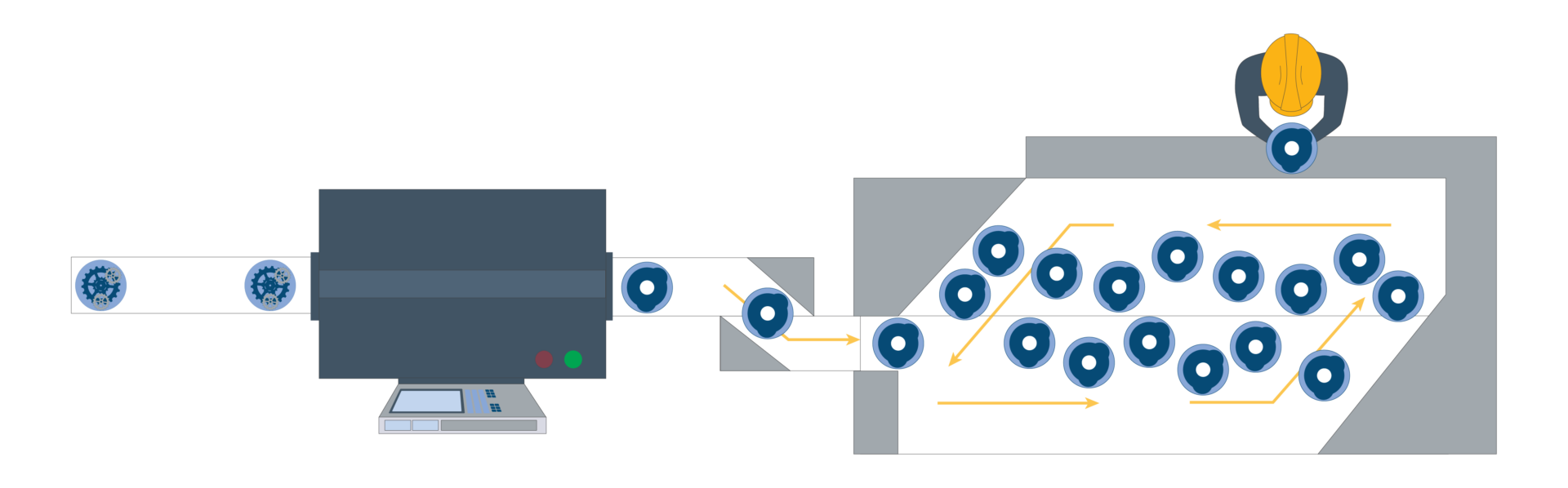

One Infeed Lane:

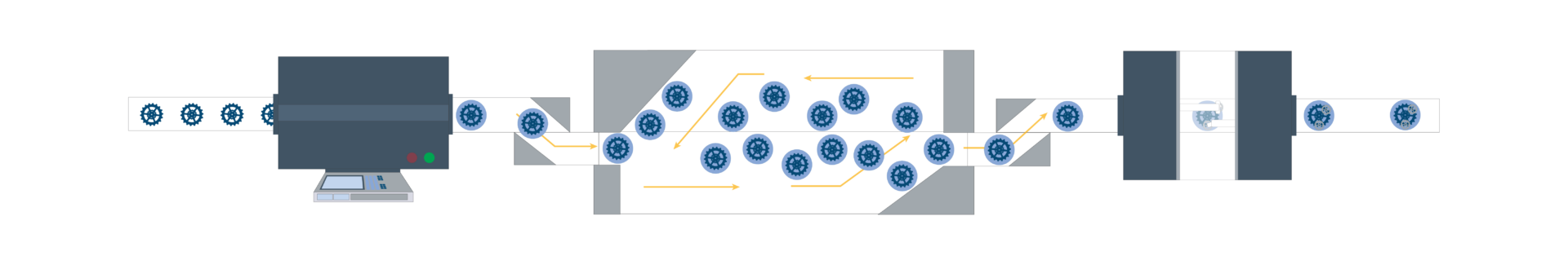

One Infeed and One Outfeed:

Used for applications where product needs to be introduced to a line in a single file, while a bulk amount of product is delivered to the table.

Used for applications where an end of the line is reached, and the output of product is an inconsistent flow rate. End-of-line accumulation prevents line backups and shutdowns due to inconsistent flow rates.

Used as an inline accumulation station to balance line and prevent upstream equipment from shutting down while maintaining maximum throughput at each machine.

Request a quote

Please provide the details about your project below. Our team will review the information and reach out to you as soon as possible.